Converging digital twin technology and Internet of Things (IoT) ecosystems showcases one of the most fundamental technological advancements in modern industrial operations. These technologies complement each other and have moved beyond theoretical applications to deliver measurable business value from manufacturing and energy to healthcare, and urban infrastructure.

Reports indicate that from 2024 to 2030, the global digital twin industry is set to expand at a compound annual growth rate (CAGR) of 35.7% from its estimated USD 16.75 billion in 2023. This robust pairing offers a proven path to operational excellence by connecting the physical and digital worlds in ways that were previously impossible.

Understanding Digital Twins and IoT: Key Concepts and Synergies

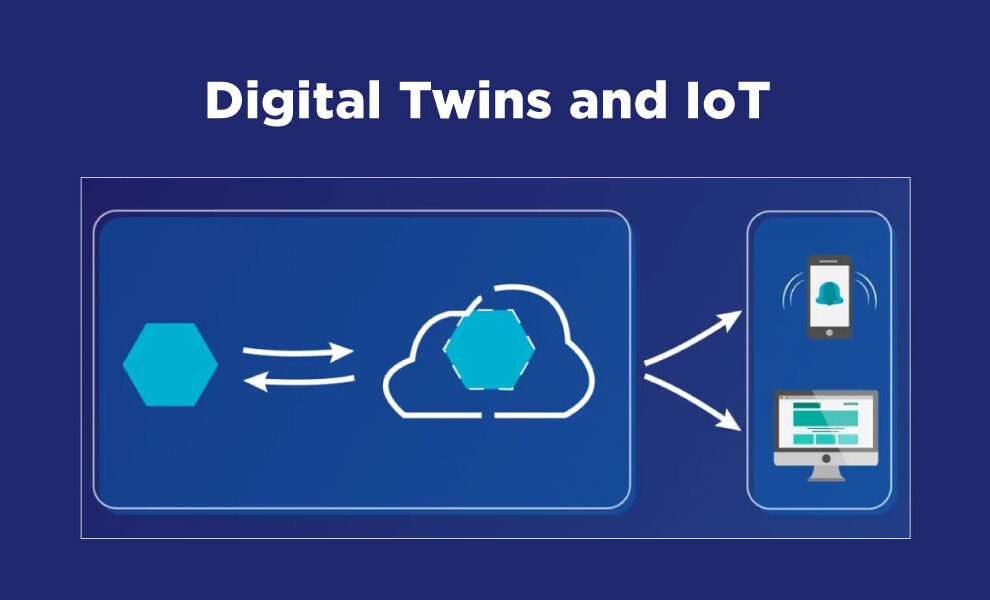

The synergy between digital twins and IoT materializes when sensor networks feed unending data streams to the virtual models, forming dynamic representations that morph close to real-time.

Digital twins plus IoT integration allows the realization of predictive maintenance through anomaly detection algorithms, operational optimization through simulation-based testing, and decision support through what-if scenario analysis. It permits the feedback loop of remote intervention in physical systems on the basis of insights from virtual simulations.

Implementation challenges include data latency issues, protocol fragmentation, edge-to-cloud bandwidth constraints, and semantic interoperability barriers. Advanced implementations involve machine learning for predictive capabilities, distributed ledger technologies for immutable audit trails, and edge computing for latency-sensitive applications.

The journey of an organization in the adoption of these technologies typically progress through stages of maturity that include connected monitoring, descriptive analytics, predictive capabilities and, ultimately, autonomous optimization where systems self-regulate based on learned performance patterns.

How Digital Twins Enhance IoT Data for Smarter Decision-Making?

Raw IoT data streams are transformed by digital twins into contextual insights. This is done by mapping information onto virtual replicas that reflect physical systems’ behaviors and characteristics. When sensor data flows into these computational models, it gains spatial and temporal context that raw data points alone cannot provide.

The integration enables scenario testing without disrupting physical operations—engineers can simulate modifications, stress test systems under extreme conditions, or evaluate optimization strategies within the virtual environment before implementation. Historical data stored within the digital twin creates a baseline for performance comparison, while real-time feeds enable deviation detection.

When new staff interact with digital twins, they gain immediate visibility into system performance history, past interventions, and operational constraints—knowledge that traditionally required years of hands-on experience.

Executives can access high-level performance indicators while technical specialists examine detailed component interactions within the same underlying model. This democratization of system understanding breaks down departmental silos, allowing maintenance, operations, design, and business teams to collaborate using a common reference point and vocabulary.

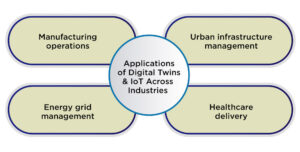

Applications of Digital Twins and IoT Across Industries

Manufacturing operations have been revolutionized through digital twin implementations that mirror production lines and equipment fleets. Factory managers leverage these virtual replicas to optimize throughput by identifying bottlenecks and simulating process modifications before physical implementation.

Urban infrastructure management benefits from citywide sensor networks coupled with comprehensive virtual models. Traffic flow optimization systems ingest data from intersection cameras, GPS transponders, and roadway sensors to create dynamic traffic twins that predict congestion patterns and adaptively adjust signal timing.

Healthcare delivery has embraced patient-specific digital twins that combine real-time monitoring with historical medical records and physiological models. Clinicians treating chronic conditions like diabetes use continuous glucose monitors and insulin pump data to create metabolic digital twins that predict glucose responses to meals, exercise, and medication adjustments.

Energy grid management relies increasingly on network-wide digital twins that model transmission infrastructure, generation assets, and consumption patterns. Grid operators use these virtual replicas to simulate the impact of renewable integration, predict maintenance needs for aging transformers, and optimize power routing during demand surges.

Challenges in Implementing Digital Twins with IoT Solutions

Data quality and integration obstacles frequently derail digital twin initiatives when organizations underestimate the complexity of merging diverse data streams. Legacy equipment lacking native sensing capabilities requires retrofit solutions that often produce inconsistent or incomplete readings.

Even with modern sensing infrastructure, timestamp misalignments between systems, irregular sampling rates, and sensor drift introduce subtle errors that compound within complex models. Organizations succeeding in this space typically establish rigorous data governance frameworks before deployment and budget 30-40% of project resources for data cleansing and normalization activities.

Security vulnerabilities multiply exponentially as the number of connected devices increases within IoT–driven digital twin ecosystems. Each additional sensor represents a potential entry point for network intrusion.

Meanwhile, the bidirectional nature of digital twins means compromised virtual environments could potentially manipulate physical systems. Industry surveys indicate that organizations typically require 18-24 months to develop the internal capability matrix necessary for the self-sufficient operation of complex digital twin environments.

Scalability constraints emerge as implementations grow from proof-of-concept to enterprise-wide deployments. Pilot projects focusing on individual assets often employ simplified architectures that collapse under the computational demands of facility-wide or fleet-level implementations.

Network bandwidth limitations, edge processing requirements, and storage architectures designed for smaller data volumes all become bottlenecks during expansion. Organizations report that scaling from pilot to production typically costs 3-5 times the initial implementation investment and often requires a fundamental redesign of the underlying architecture to support the increased data velocity and volume.

The Future of Digital Twins and IoT: Trends and Innovations

Physics-based digital twins are evolving toward autonomous operation through enhanced modeling capabilities that incorporate real-world behaviors at unprecedented fidelity. Next-generation simulations will incorporate material degradation patterns, fluid dynamics, and thermal interactions—allowing virtual replicas to predict failures without explicit programming.

Cross-domain integration is another trend set to eliminate current silos between manufacturing, supply chain, and product lifecycle twins. This interconnection will enable true end-to-end optimization where product design modifications automatically trigger manufacturing process adjustments and supply chain reconfiguration without manual intervention.

Edge-cloud hybrid architectures will resolve current limitations in bandwidth and latency that constrain real-time decision-making. Processing-intensive components of digital twin workloads will migrate to edge computing infrastructure located physically near the monitored assets, while cloud resources will handle longer-term analytics and cross-system optimization.

Alongside that, immersive visualization interfaces also hold the potential to transform how teams interact with digital twins through spatial computing technologies. Rather than viewing system data on traditional screens, engineers will use augmented reality to overlay digital twin information directly onto physical assets during inspection and maintenance activities.

For more informative and helpful content, keep visiting us at HiTechNectar.

You May Also Like to Read:

Blockchain and Digital Twins: Amalgamating the Technologies

Examining the Internet of Things (IoT), its Major Applications, and Outlook